This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

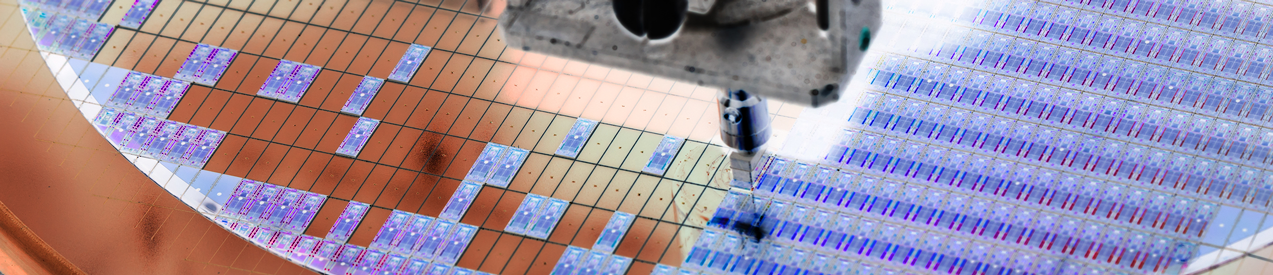

Systema is a global company specializing in automation and software solutions for manufacturing processes. It cooperates with the world’s largest semiconductor producers, helping them digitize and supporting the entire value chain from production to testing. Systema provides services such as system integration, manufacturing execution systems (MES), and digital transformation.

Challenge

Systema sought high-end Java developers with legacy code experience for a semiconductor client. The aim was to upgrade the MES, automate workflows, and create a stable base for a “Smart Factory.”

Solution

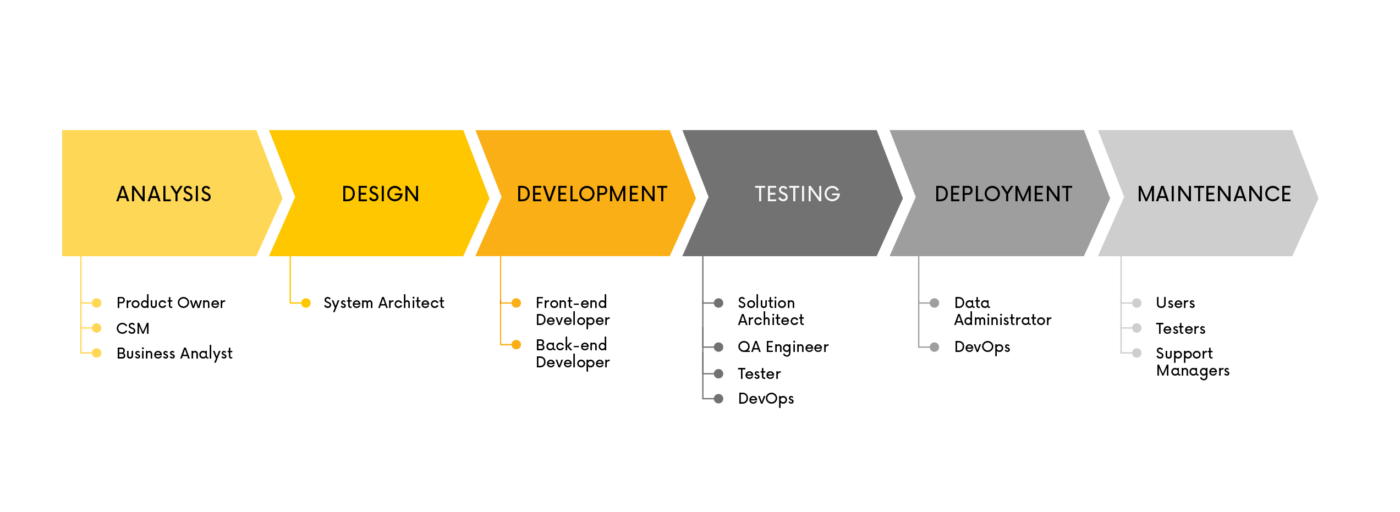

Our cooperation was divided into several stages, from advisory services to development and testing at the client’s site.

Advisory stage

After developing a concept for an automated production management system for integrated circuits, we hired a business analyst to collaborate with the client’s team. They created a business concept, solution design, and functional requirements, documenting their analysis in BPMN, UML, and Enterprise Architect.

Development

We provided the software architecture, developed the source code, and tested the product. Our work included:

- Dedicated SAP MES interfaces, customization of database structures, and consulting

Our developers created custom solutions for one part of the SAP system used by the client. They worked with SAP ERP, which has a plant maintenance module (SAP PM) connected to a custom MES. SAP PM manages equipment maintenance, including schedules and technician skills. Our developers wrote SAP interfaces, customized databases, and provided technical advice.

- Integrating machines into the automation landscape

Our programmers developed an automation layer that controls machine processes and connects them to the MES and external systems. One of Systema’s products is a Java application consisting of two modules. Developers integrate them with other devices and customize them for specific machines. Machine integration speeds up operators’ work and provides several hundred pieces of measurement data.

- Semiconductor and manufacturing management software

In this project, our developers created custom software for the end-customers in semiconductor and manufacturing automation companies. The project’s scope included production path automation tasks like system interconnection, machine software, and archiving. The solution is based on microservices. Two web-based user interfaces are also part of the solution—one configures the production process, and the other oversees its progress.

Implementations included:

- A master data management system for the factory’s “digital twin.” It set up the system’s master data

- An execution engine for running automated manufacturing tasks

- The underlying framework for system integration and communication

Results

As part of these complex projects, more than 20 VM.pl team members have quickly helped develop the client’s systems. We are working with world-class companies and the client’s team.

From the customer

The most impressive thing is the way they work with us. They are fully interested in our success, and associates are constantly evaluated by VM.PL. They are often already working on shortcomings before we mention it to them. Their in-house training is very effective and shows rapid improvement.

Technologies

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.