This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

One of the global manufacturing companies, supplying specialized laboratory equipment, serves over 5,000 customers in 110 countries. Every day, it processes hundreds of orders arriving in various formats — PDF, Excel, emails, and online forms.

Challenge

The order processing department consisted of 15 employees, whose main task was manually entering data from documents into the SAP system.

Key challenges faced by the client included:

- High operational cost: 15 full-time positions × €8,000 per month

- Limited scalability: Any increase in order volume required hiring additional staff

- Data source diversity: Orders arrived in various formats and multiple languages

- Risk of errors and delays due to manual data entry

Solution

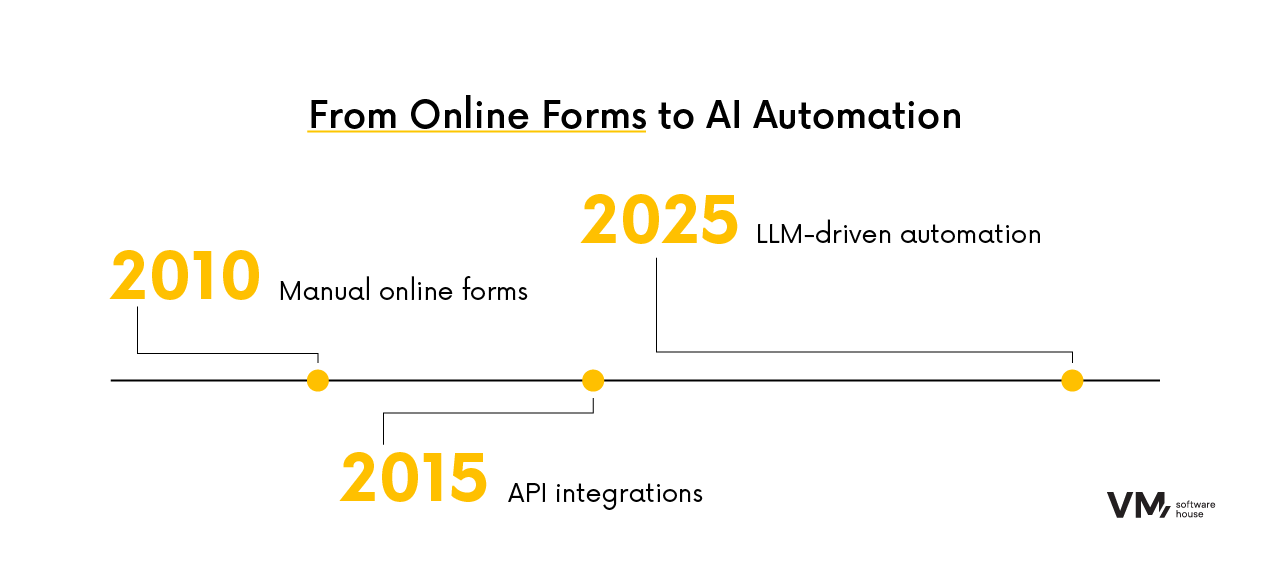

How it would have looked in the past – and how it works today

2010 – Online order form

If this challenge had arisen in 2010, we would have proposed creating an online order form where biotech clients could manually submit order details. It would have been a first step toward digitalization, eliminating the need to retype data from emails, PDFs, or scanned documents.

2015 – API integrations

By 2015, we would likely have implemented API integrations to connect client sales systems directly with the biotech company’s ERP platform.

2025 – AI and LLM-powered automation

In 2025, orders—regardless of format or language—are automatically processed by a system powered by large language models (LLMs). Artificial intelligence understands context, extracts products, quantities, and prices, maps the data to SAP structures, and forwards it without human involvement. A five-person team now handles only edge cases.

How We Achieved It

Our goal was to completely eliminate manual data entry into SAP—without requiring clients to change their habits. Customers could continue submitting orders in various formats and languages.

Step 1: Process mapping and pain point identification

We began by mapping the actual order flow within the company—analyzing channels, formats, and the role of the order management team. Orders were received via emails, PDFs, Excel files, scans, and online forms, often in multiple languages and layouts, due to the company’s global reach (110+ countries). The main challenge was not just the variety of sources, but also the lack of standardization and the high variability of input data.

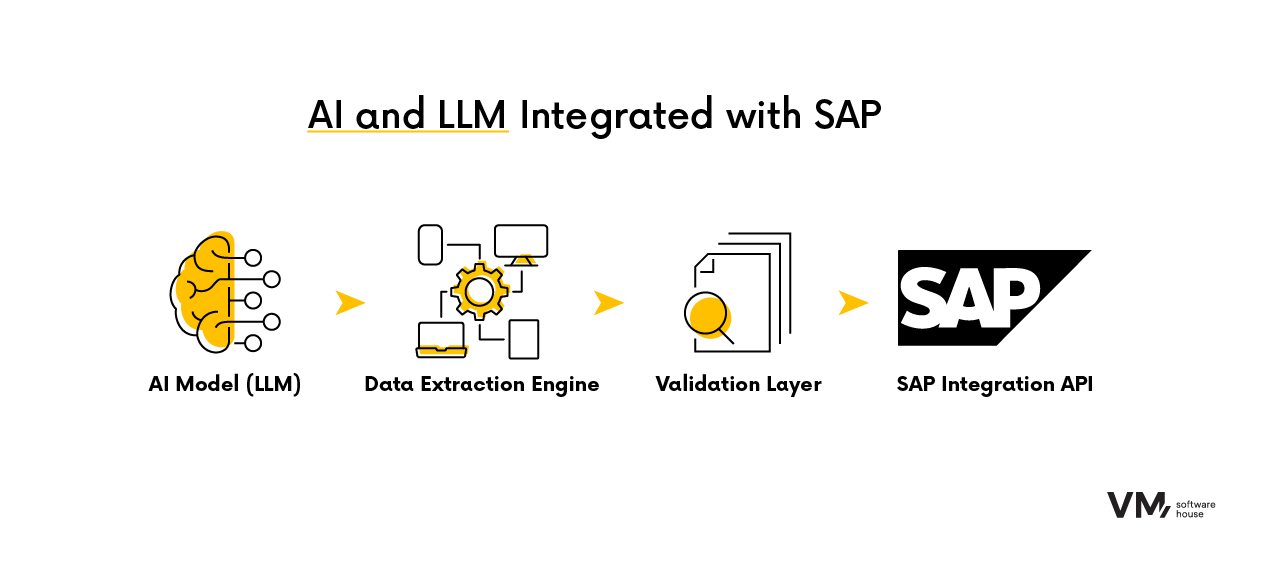

Step 2: Solution architecture design

We built a hybrid system composed of:

- AI module powered by LLMs – to interpret contextual information from documents

- Data extraction engine – handling OCR, table parsing, and field detection

- Data validator – checking completeness, accuracy, and SAP compliance

- SAP integration API – directly posting structured data into the ERP system without human intervention

Step 3: Fine-tuning the model on client data

We trained the model on real client documents (in full compliance with data protection regulations), enabling:

- Recognition of product names and material codes

- Matching of units, pricing, and contract terms

- Understanding of multilingual order context

Step 4: Implementation and continuous optimization

After deploying into the production environment, the system was monitored and refined based on real use cases. Within six months, we achieved over 90% order processing accuracy—fully automated, without operator input.

Key advantages of the solution:

- Works with any input format – no standardization required from end clients

- Continuously learns – each document improves the model

- Reduces response time and eliminates human error

- Fully integrated with SAP – no changes needed on the ERP side

Solution

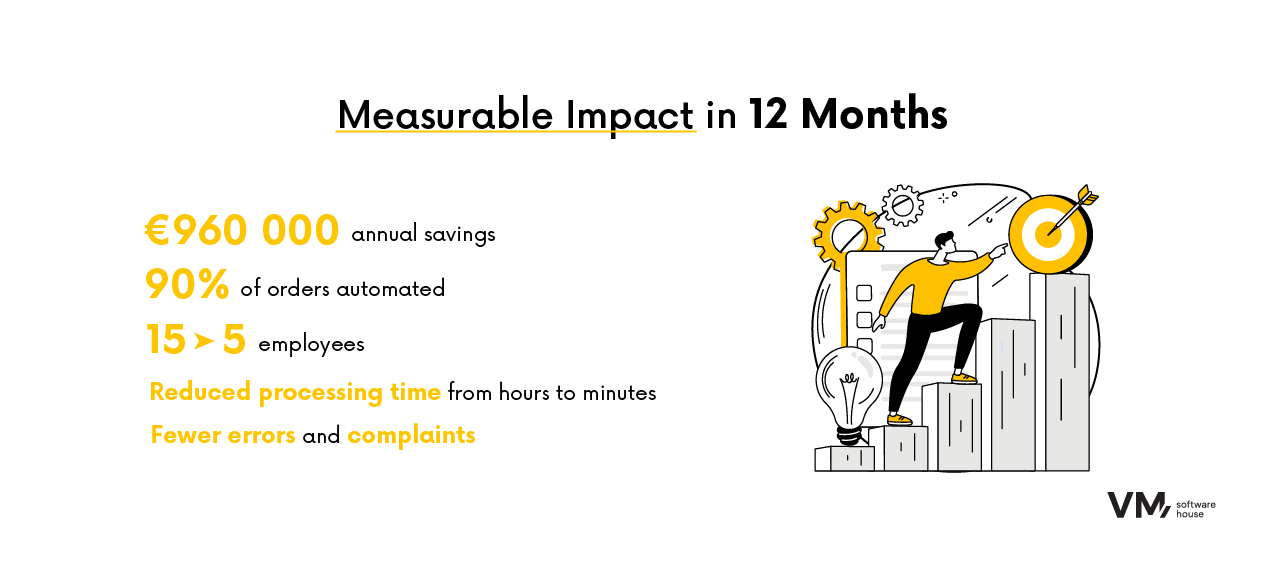

The AI and LLM-powered solution completely transformed the client’s order handling process.

Instead of a 15-person team manually inputting data into SAP, just 5 employees now oversee and manage exceptions. The client not only significantly reduced operational costs, but also positioned the company for future growth—without needing to scale headcount.

Key outcomes:

- €960,000 saved annually

- Order processing time reduced from several hours to a few minutes

- Over 90% of orders now flow into SAP fully automatically

- Scalability with zero marginal cost – the system handles increasing order volume and new formats

- Fewer errors and complaints – data reaches SAP exactly as required

- Improved customer satisfaction – faster fulfillment, fewer mistakes, and predictable service

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.