This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

The project was executed for a provider of advanced automation solutions for microbiology laboratories. The AI-powered tool was deployed at the end customer — one of the world’s top 10 pharmaceutical companies, operating on a global scale.

Challenge

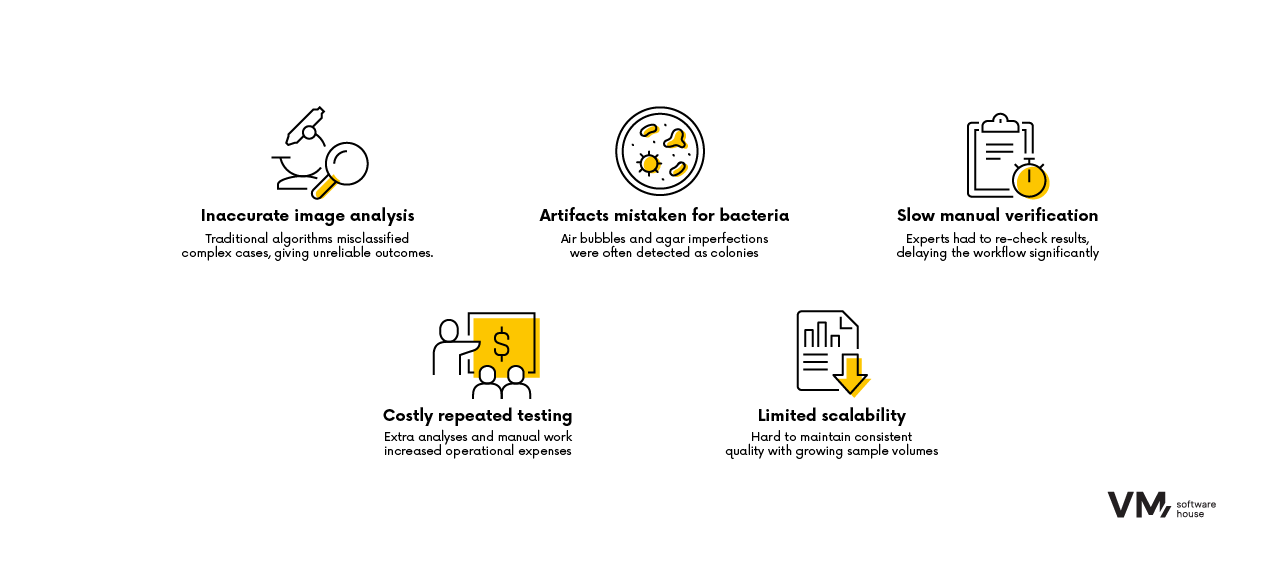

In the pharmaceutical sector, the quality and precision of microbiological analysis are critical. The existing system, based on traditional computer vision algorithms, failed to meet the required accuracy standards — frequently misidentifying small artifacts such as air bubbles in agar as bacterial colonies. These false positives not only delayed the verification process but also incurred additional costs due to manual inspection and retesting. The client required a more precise, scalable, and reliable solution — one that could function without the need for expensive optical hardware upgrades.

Solution

A new image analysis module based on deep learning was designed specifically for the needs of industrial microbiology. The work went beyond AI model development and included upstream project support:

- Detailed analysis of the problem and expected business outcomes

- Consulting on the collection and annotation of training data essential for model performance

- Implementation and training of a bacterial colony detection model using deep learning techniques

- Full integration of the solution with the laboratory’s existing environmental monitoring system

A critical design decision was made: instead of relying on expensive multispectral cameras — whose quality proved insufficient for such sensitive analyses — the project focused on the power of artificial intelligence and machine learning.

Results

The implemented system marked a significant breakthrough — both technologically and operationally:

- Improved image analysis accuracy in cases traditionally challenging for classical algorithms (e.g., colonies near the edge of the plate, agar inconsistencies, artifacts)

- Eliminated the need for manual sample review by specialists, resulting in measurable cost savings and increased operational efficiency

- Accelerated analysis and improved repeatability — crucial for scaling operations while maintaining consistent quality standards

- Potential to adapt the solution across other industries that require high-precision image analysis: medical diagnostics, pharmaceutical quality control, and industrial microbiology

By leveraging artificial intelligence, the project delivered not only better technical performance but also enhanced process reliability in the context of regulatory and business demands.

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.