Handling data in a production environment comes with numerous challenges. In this article, we show how the OPC Gateway streamlines the management of isolated data storage, the integration of legacy machines, and real-time data access. We explain the technology, the flow of data from the shop floor to the cloud and provide examples of its role in digitizing the shop floor. We also explore how the OPC Gateway contributes to real-time data analysis, process optimization, and sustainable implementation. Finally, we discuss the future of the OPC UA standard and the Industrial Internet of Things (IIoT).

Table of Contents

Definition and Role: What Is an OPC Gateway and Its Importance in Connected Production?

An OPC Gateway is a tool based on the OPC UA protocol, which is one of the key communication standards for Industry 4.0. It is a platform-independent standard that ensures secure and reliable data exchange in industrial environments. Data is collected from various sources and centrally analyzed. However, before this can happen, it’s necessary to translate different communication protocols into a common language, allowing for unified data processing. One of the system’s main advantages is its real-time capability—meaning data is processed and transmitted instantly. This is a major benefit, as it eliminates so-called data silos, or the issue of storing information in isolated systems.

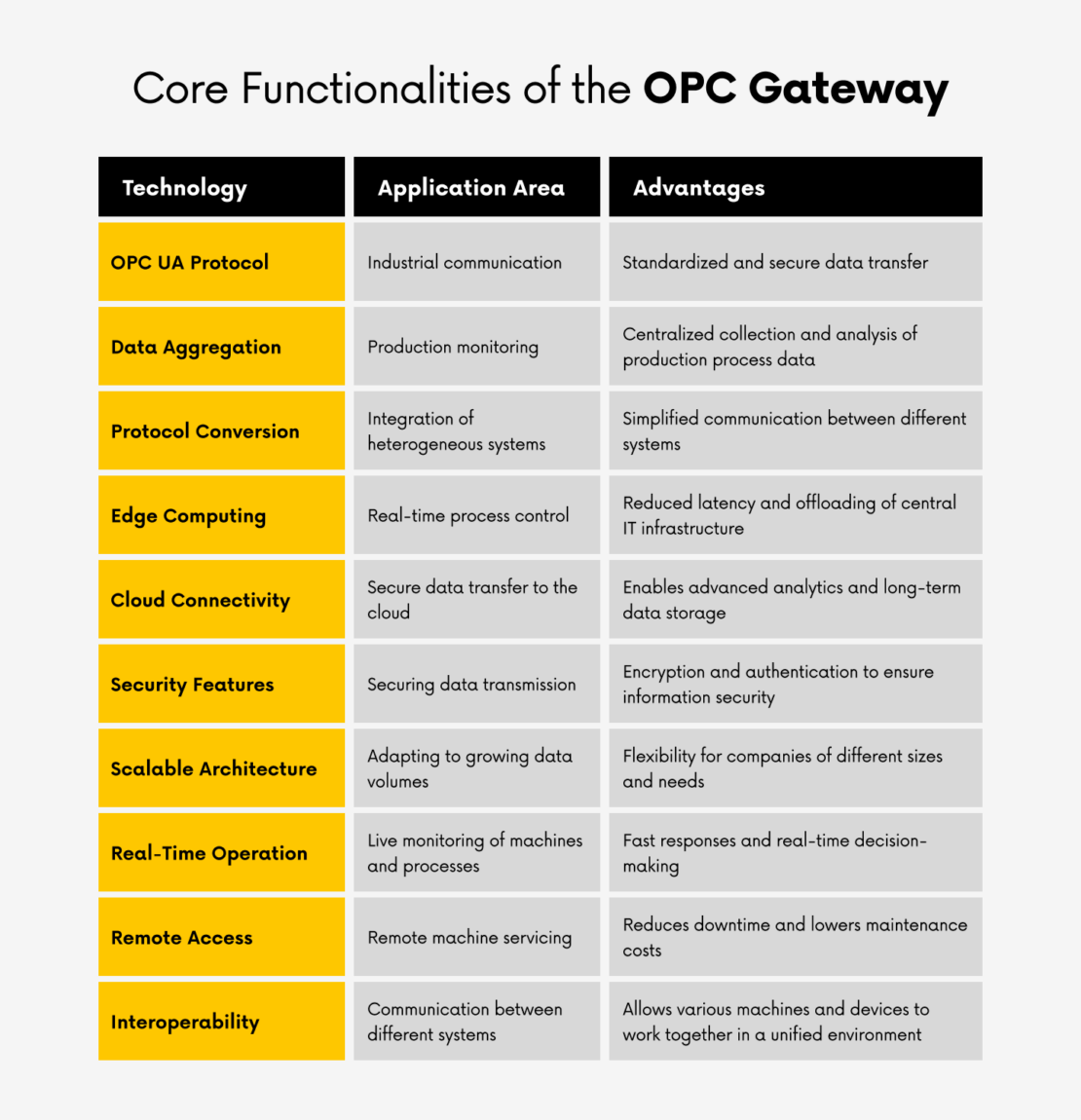

In the table below, we’ve outlined the key aspects of the OPC Gateway and highlighted its most important benefits:

Data Flow from the Shop Floor to the Cloud: Seamless Integration with Modern Systems

The gateway effectively integrates production data with higher-level systems, transmitting it in real time to the cloud while still supporting legacy systems. Standard communication protocols such as OPC UA are used, allowing seamless integration of machines and systems from various manufacturers. Production data is standardized and analyzed using cloud services.

The cloud enables access to data anytime and from anywhere, making it possible to leverage that data for a wide range of analyses. To ensure constant data availability, the gateway automatically synchronizes the information. The collected data can then be analyzed and clearly visualized using data visualization tools.

All of this supports optimized production planning—including scheduling service windows, managing material supplies, and coordinating production resources.

Data Integration Challenges: Why Traditional Approaches Fail

Legacy Machines and Lack of Interfaces: Many factories struggle to adopt modern technologies, especially when dealing with older machines that often lack modern data transfer interfaces. In such cases, the OPC Gateway can effectively “add” the missing interface, enabling data transmission to modern systems. Compared to purchasing new machines with built-in interfaces, this is a highly cost-effective solution.

Heterogeneous Systems: Another major challenge in many enterprises is the coexistence of different systems that cannot communicate with one another. The OPC Gateway addresses this issue by translating data from various systems into a common language, enabling smooth and standardized communication across platforms.

Lack of Real-Time Data: Previously, production data was only available with delays. The OPC Gateway enables real-time data transmission, allowing for faster and more accurate decision-making.

Other Challenges: The OPC Gateway also tackles problems such as poor data quality—by using standardized methods of data acquisition and aggregation—as well as complex system integration and many other hurdles associated with production digitalization.

Real-Time Analysis and Process Optimization: The Role of the OPC Gateway

The OPC Gateway delivers a range of powerful capabilities that accelerate data-driven decision-making and help minimize production downtime.

Here are the 10 most important use cases for the OPC Gateway:

- Process Monitoring

The OPC Gateway monitors all production processes in real time, identifying inefficiencies at an early stage. - Predictive Maintenance

By continuously analyzing machine data, it can detect maintenance needs ahead of time and schedule service activities without disrupting production workflows. - Production Efficiency Optimization

Based on the collected data, the gateway identifies bottlenecks and enables corrective actions, leading to increased production line throughput. - Error Detection and Quality Control

When deviations occur in the production process, the system instantly detects them and triggers corrective measures, ensuring consistently high product quality. - Data-Driven Decision-Making

With all critical systems monitored in real time, decisions can be made swiftly and based on reliable, up-to-date insights. - Energy Consumption Optimization

Data collected by the OPC Gateway can be analyzed to reduce energy usage, ultimately lowering energy costs. - Improved Communication

By integrating data from multiple sources, the gateway enhances information flow across production departments, improving operational coherence. - Downtime Reduction

Predictive maintenance not only optimizes operations but also significantly reduces unplanned production downtime. - Increased Flexibility

In response to market changes, the system can quickly adapt production processes to meet new demands—boosting overall business agility. - Greater Transparency

Since all production data is accessible to employees in real time, full operational transparency is maintained throughout the organization.

Best Practices for Implementing and Operating OPC UA Gateways

Network security and scalability are critical concerns in modern IT solutions. Therefore, it is essential that …

… data transmission between machines utilizes encryption technologies such as TLS/SSL to ensure secure communication.

… access to specific data is restricted to authorized personnel only, through well-defined access control mechanisms.

… data integrity is maintained through checksums and hash algorithms, guaranteeing the immutability of data during transmission.

… redundant systems and backup mechanisms are implemented to prevent data loss and ensure system resilience.

… cloud infrastructure is leveraged to scale the OPC Gateway architecture, allowing for flexible system expansion as data processing demands grow.

Other key aspects include real-time monitoring and alert systems, automated software updates, integration with firewalls, and eliminating single points of failure (SPOF) to enhance system reliability and uptime.

Looking Ahead: OPC UA, the Industrial Internet of Things (IIoT), and Next-Generation Factories

All indicators point to significant advancements in existing technologies over the coming years, as well as the emergence of entirely new solutions. With 5G technology, real-time data transmission will become even faster, while artificial intelligence will improve forecasting accuracy and enable more efficient optimization. The level of autonomy in machines and systems will continue to grow, and OPC Gateways will serve as crucial communication bridges.

In the realm of the Industrial Internet of Things (IIoT), OPC Gateways will play an increasingly central role, facilitating seamless communication between machines and systems.

It is therefore highly advisable to engage with this rapidly evolving field as early as possible. Already today—and even more so in the future—it is becoming the standard for optimizing production throughput and process efficiency.

More detailed information on this topic can be found in our case study, where we describe the implementation of the OPC Gateway for one of our clients. There, you’ll learn how we capture sensor data, implement asynchronous communication, and provide remote software maintenance services—without the need for physical presence or connecting via TeamViewer.