This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

Toyota Motor Manufacturing Poland is a key production facility of the Japanese automotive giant in Europe, located in Wałbrzych. The factory specializes in manufacturing advanced engines and transmissions for hybrid vehicles, supplying Toyota assembly plants across the continent. The client operates in a highly automated production environment and collaborates closely with engineering teams from Japan on the design and implementation of new technology lines.

Challenge

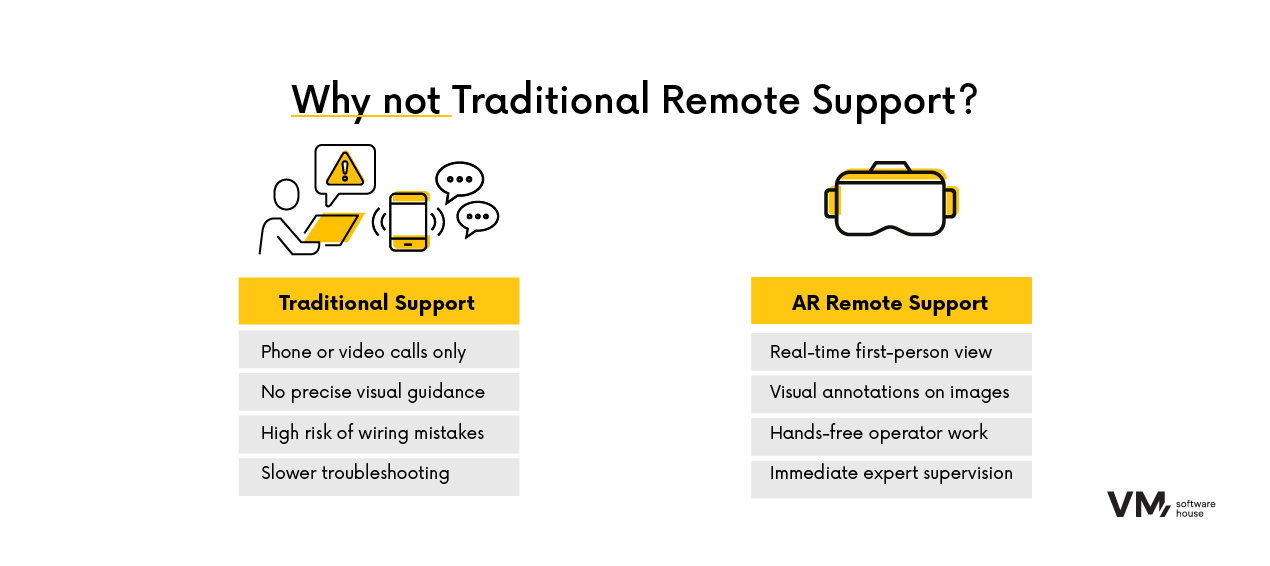

During the COVID-19 pandemic, Toyota faced an urgent task: launching a new, advanced production line. The line was designed by engineers in Japan, but its installation and configuration had to take place at the manufacturing plant in Wałbrzych, Poland.

Due to travel restrictions, the physical presence of Japanese experts was not possible. However, critical assembly stages—such as wiring a complex electrical cabinet with hundreds of cables—required precise instructions and expert oversight. Any error in the wiring could lead to system failure, delays, or costly production downtime.

Toyota needed a solution that would enable remote, accurate, and intuitive transfer of technical know-how, allowing Japanese experts to supervise operator activities in real time—from the other side of the world.

Solution

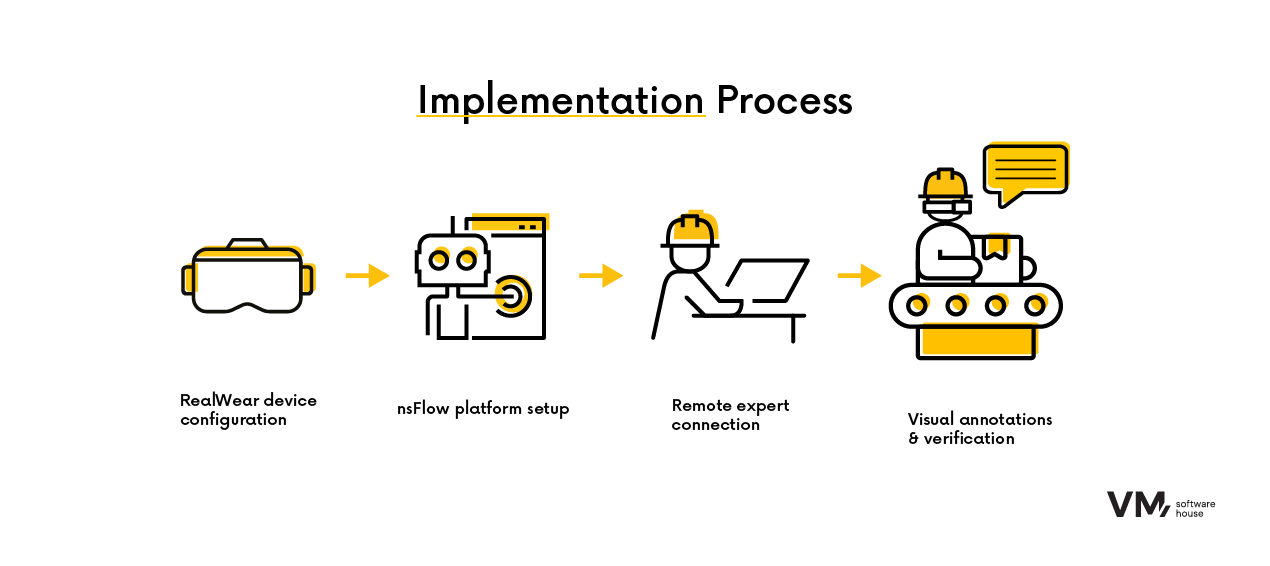

To address the client’s needs, the AR Remote Support module was implemented, powered by the nsFlow platform and RealWear industrial smart glasses. This technology enabled real-time remote support using augmented reality and audiovisual communication.

Operators in Poland were equipped with AR glasses that allowed them to work hands-free—performing tasks without interruption while remaining connected to remote experts. Key features of the implemented solution included:

- Real-time video feed – Japanese engineers had continuous access to the live camera feed from the operator’s glasses.

- Remote annotations on images – At critical moments, engineers could freeze the video, mark instructions (e.g., “third cable from the right”), and send annotated images to the operator.

- Full audiovisual communication – Support was provided through voice and visuals, with no need for hand-held devices.

- Simple setup – Consultations could start with just a link—no programming skills or complex configuration required.

- Compliance with safety standards – RealWear glasses were fully compatible with industrial environments, allowing the use of helmets, gloves, and protective eyewear.

Thanks to this setup, experts could remotely supervise the assembly of the electrical cabinet—pointing out exact components and cables to connect, and correcting any errors in real time.

Results

The impact of the implementation was almost immediate—financially, operationally, and environmentally:

- Reduced travel and accommodation costs – Eliminating international travel (from Japan to Poland) resulted in savings of several thousand euros for each deployment iteration.

- Faster implementation time – Instant access to remote experts helped avoid downtime and delays, significantly accelerating the production line launch.

- Greater precision and reduced risk of errors – The ability to annotate images visually drastically reduced the risk of incorrect component connections.

- Increased employee confidence – Operators felt supported and reassured by having real-time access to expert guidance—even for seemingly minor uncertainties.

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.