This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

Toyota Motor Manufacturing Poland’s Wałbrzych branch is a modern production facility specializing in drivetrain components for hybrid vehicles. Due to rapid growth and rising demand for new operational staff, the company faced a significant training challenge.

Challenge

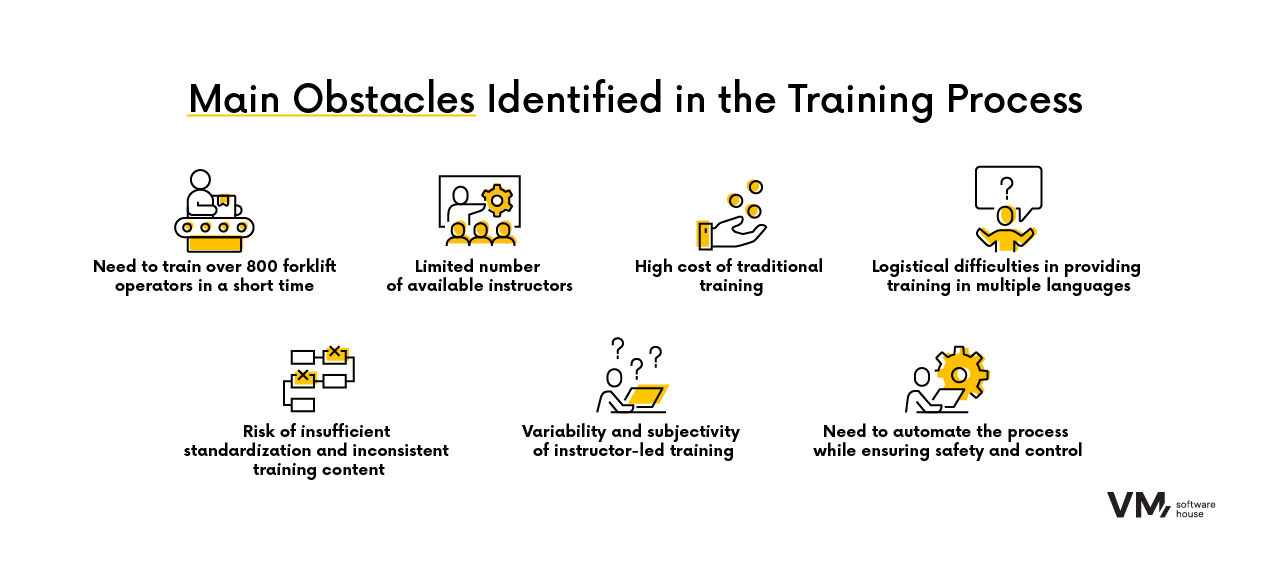

As part of expanding its production team, Toyota faced the need to train over 800 forklift operators in a short period of time.

Traditional training methods posed several challenges:

- High costs of conventional training requiring in-person instructors and dedicated physical space

- Limited number of instructors, slowing down the training process

- Logistical difficulties in providing multilingual training

- Inability to scale the process quickly — running multiple parallel sessions was difficult

- Risk of inconsistent messaging and lack of standardization — training quality varied depending on individual instructors

Toyota needed a solution that could automate and standardize the training process with minimal human involvement, while ensuring safety, control, and effectiveness.

Solution

When we proposed the project, we started with a simple question: What if every trainee had their own personal digital instructor—always available, always precise, monitoring every move?

The answer was an AR (Augmented Reality) system that works both online and offline—independent of constant network connectivity, which is critical in industrial environments where signal interruptions are common.

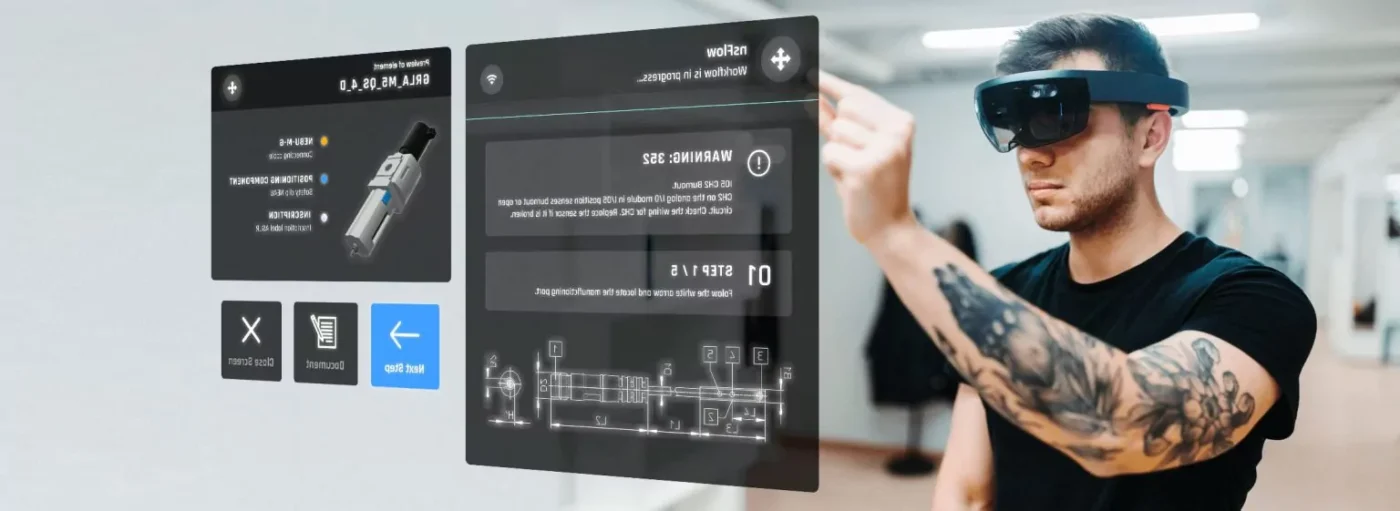

Instead of immersing the employee in a virtual world, the AR system overlays digital guidance onto the real-world view through smart glasses. Without obstructing vision or causing distraction, semi-transparent prompts appear—text, graphics, instructional videos, or arrows showing what to do and where to go. Operators see their actual production floor while receiving real-time guidance.

For example, at one stage, a message appears: “Use designated support points,” followed by a step-by-step guide: “Grab the pillar handle,” “Place foot on the step,” “Pull yourself up and enter the vehicle,” etc. A video or reference image can also be shown.

Task verification happens automatically. Ceiling-mounted and vehicle-mounted cameras analyze the operator’s movements: whether they entered correctly, fastened the seatbelt, and approached the rack with the right fork positioning. Even vehicles lacking telematics weren’t an issue—the implementation team used computer vision and camera calibration to precisely measure tilt angles, lift heights, and distances to targets.

This approach enabled the creation of a modern training process that not only accelerated onboarding but also improved task quality and operational safety.

Check out the video to see how AR technology can automate training and significantly shorten employee onboarding: https://www.youtube.com/watch?v=SvGVKC7U-h0

Result

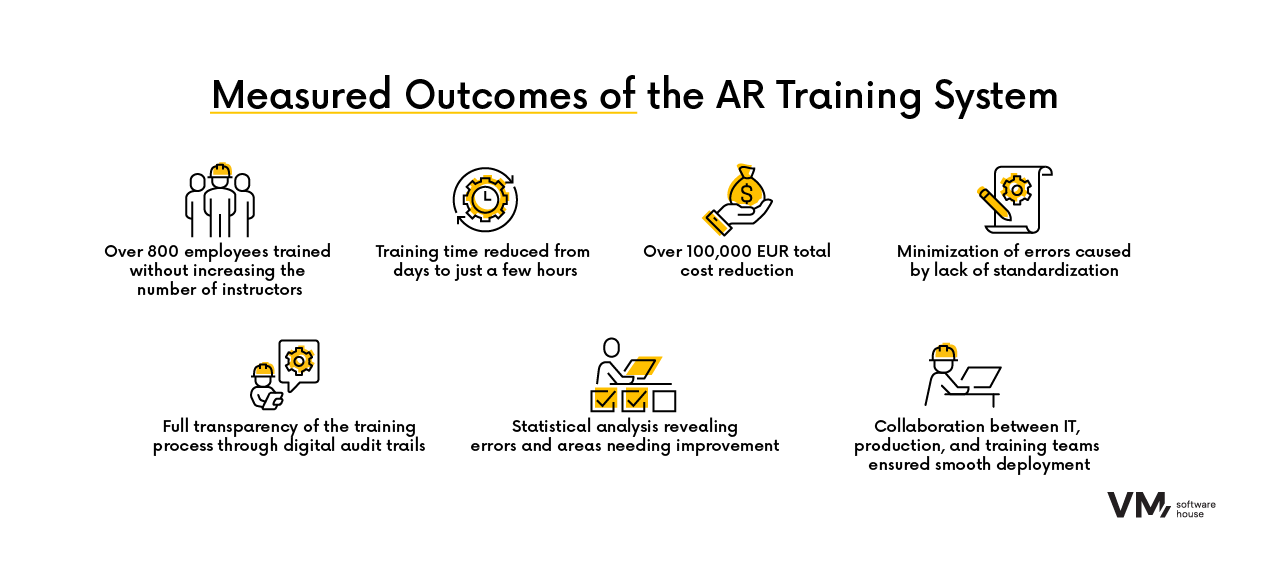

Thanks to the implementation of the new solution, over 800 employees were successfully trained without the need to increase the number of instructors. A process that previously took several days was reduced to just a few hours.

The digitalization delivered tangible savings—around 130 EUR per person, totaling over 100 000 EUR in cost reductions across the project. Additionally, non-productive time was significantly reduced, and the risk of errrs due to inconsistent training was minimized.

Standardized training ensured that every employee followed the exact same learning path—the same steps, in the same order, with the same content. This eliminated discrepancies in skill levels across the workforce.

The introduction of automated auditing and digital training records brought full transparency. Statistical analysis became possible: identifying who makes the most mistakes, which stages need refinement, and where additional guidance could be added.

The project’s success was driven by several key factors: clearly defined client needs, openness to adopting new technologies, and the flexibility of the project team, which adapted the solution to technical limitations—such as the lack of data interfaces in older forklift models. Seamless integration into daily operations was achieved through close collaboration between IT, production, and training departments.

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.