This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

The client operates a last-mile delivery logistics business in a major urban area. In line with its urban transport decarbonization strategy, the company transitioned to an electric vehicle (EV) fleet. However, it faced constraints due to the limited number of available charging points and operational instability (vehicle breakdowns, unexpected delays, and grid overloads).

The fleet included several dozen EVs handling hundreds of orders daily. To maintain operational continuity, a system was needed to dynamically and efficiently manage vehicle charging—regardless of disruptions throughout the day.

Challenge

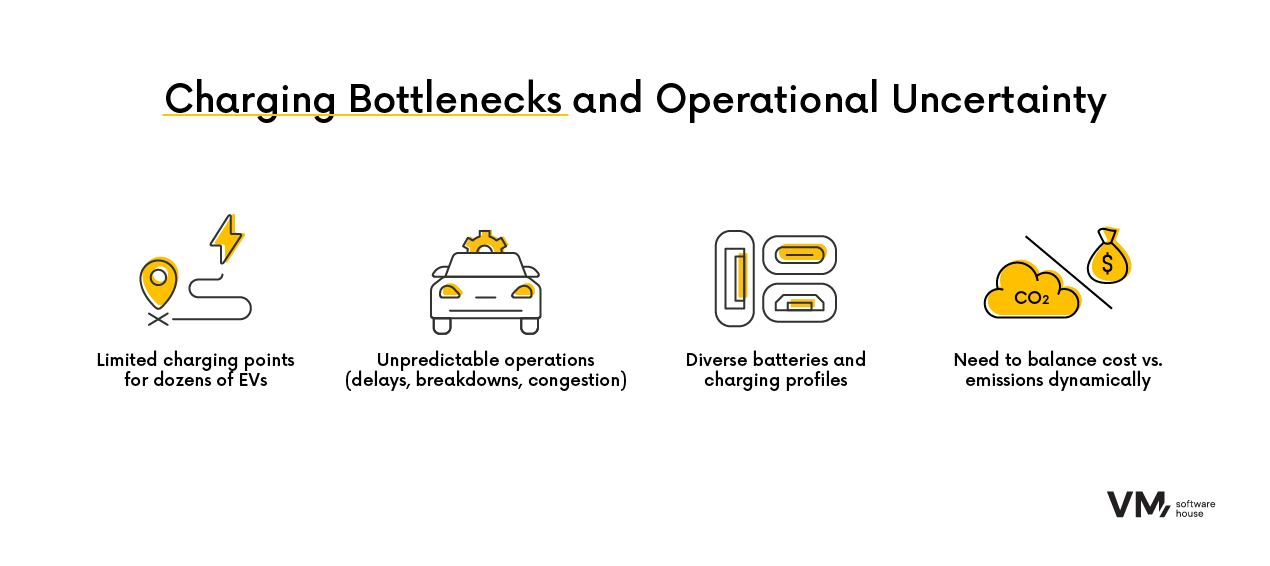

As EV delivery operations scaled, the client needed to optimize the vehicle charging process. Traditional methods—based on static schedules or manual control—proved inadequate given limited infrastructure, high operational variability, and increasing demands for cost and environmental efficiency. Key challenges included:

- Limited charging infrastructure: Only a few charging stations available for dozens of vehicles

- High operational variability: Breakdowns, delays, traffic congestion, and unpredictable changes in vehicle availability

- Technical complexity: Different plug types, battery profiles, and charging behaviors

- Diverse optimization goals: The need to switch flexibly between cost reduction and carbon footprint minimization based on shifting company priorities

Solution

We began with a joint analytical workshop to understand the fleet’s operations and identify key constraints and variables affecting the charging process. Based on this, we created an abstract model of the charging system that included:

- The infrastructure topology and electrical parameters of charging stations

- Vehicle schedules and energy demand

- Random factors such as breakdowns, traffic congestion, or task changes

This model formed the foundation for a solution composed of two main components:

- Domain-Specific Language (DSL) – A tool for describing infrastructure, vehicles, and operational constraints in a way that is understandable to both technical and logistics teams. It allows for rapid configuration and testing of various charging scenarios without writing code.

- Optimization Engine – Designed to solve complex decision-making problems in real time. The system automatically selects the optimal charging plan based on current data and the chosen objective (cost or CO₂ emission minimization), while also adapting to unforeseen events with response times measured in seconds.

The solution was built to be modular and flexible—making it applicable to other contexts, such as optimizing public bus charging or using EV batteries as energy storage.

Results

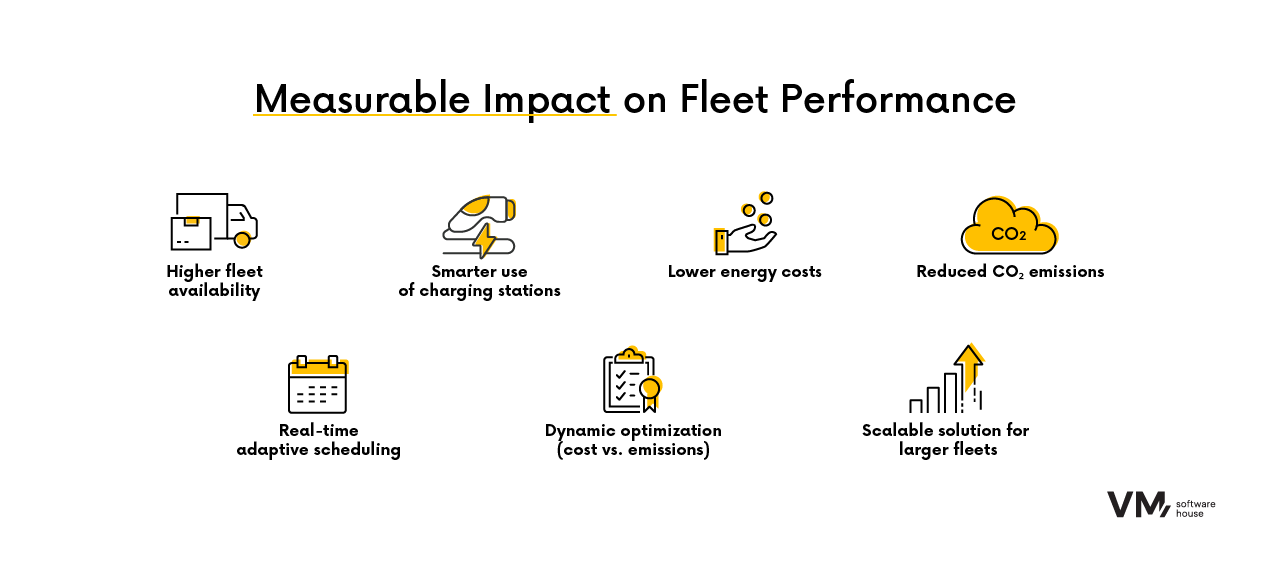

The system implementation led to significant improvements in operational processes and more efficient use of charging infrastructure. Key benefits included:

- Reduced vehicle downtime caused by suboptimal charging schedules, resulting in improved fleet availability and a higher number of completed deliveries

- Lower electricity costs through off-peak charging and reduced reliance on emergency charging

- Reduced CO₂ emissions in eco-mode by prioritizing renewable-powered stations and avoiding charging during peak grid demand hours

These benefits enabled the client to not only enhance operational efficiency but also achieve key sustainability goals.

How We Saved €960K Per Year by Reducing the Order Management Team from 15 to 5 with AI and LLMs

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.