This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Client

An international pharmaceutical company operating in over 100 countries, specializing in unit-dose drug packaging. The facility involved in the project is in Europe and subject to strict pharmaceutical industry regulations.

Challenge

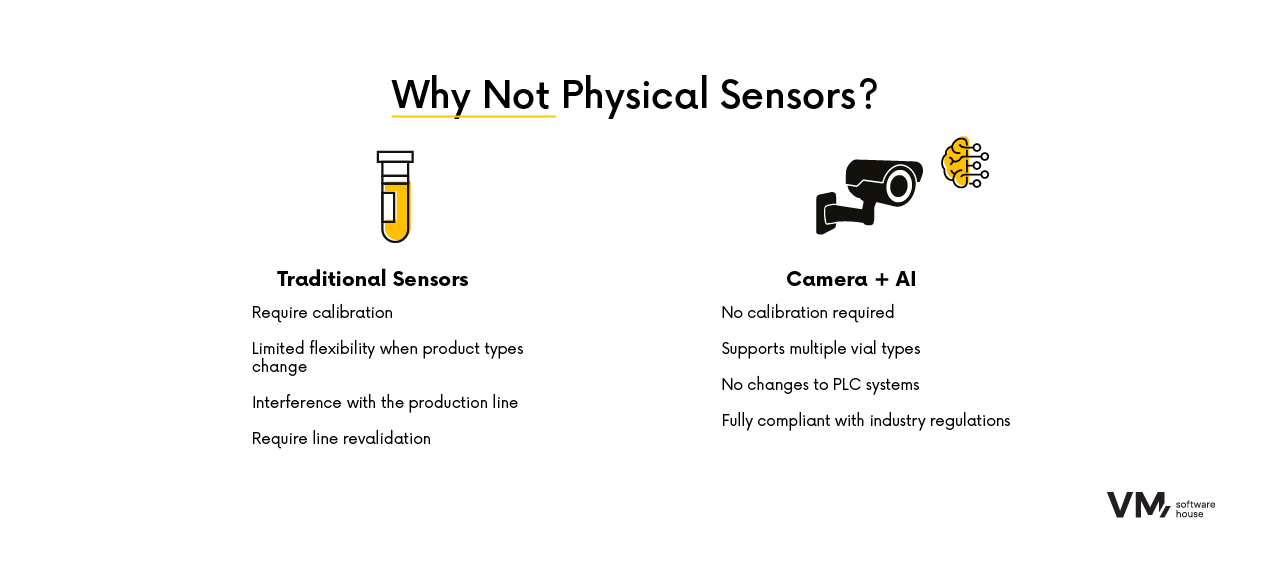

The production facility faced frequent downtime on the packaging line caused by vials tipping over on the conveyor belt. The issue affected 7 different vial types—both glass and plastic—ranging from 7 to 100 ml in volume. This product diversity made traditional physical sensors unsuitable, as they would require time-consuming calibration and were prone to errors.

An additional challenge stemmed from regulatory constraints—any changes to the machinery or PLC software would require revalidation of the entire line, which in pharmaceutical environments leads to weeks of delays and significant costs.

The goal was to implement a solution that would:

- Detect fallen vials in real time

- Require no modifications to machine construction

- Withstand varying environmental conditions

- Allow fast implementation and easy scalability

Solution

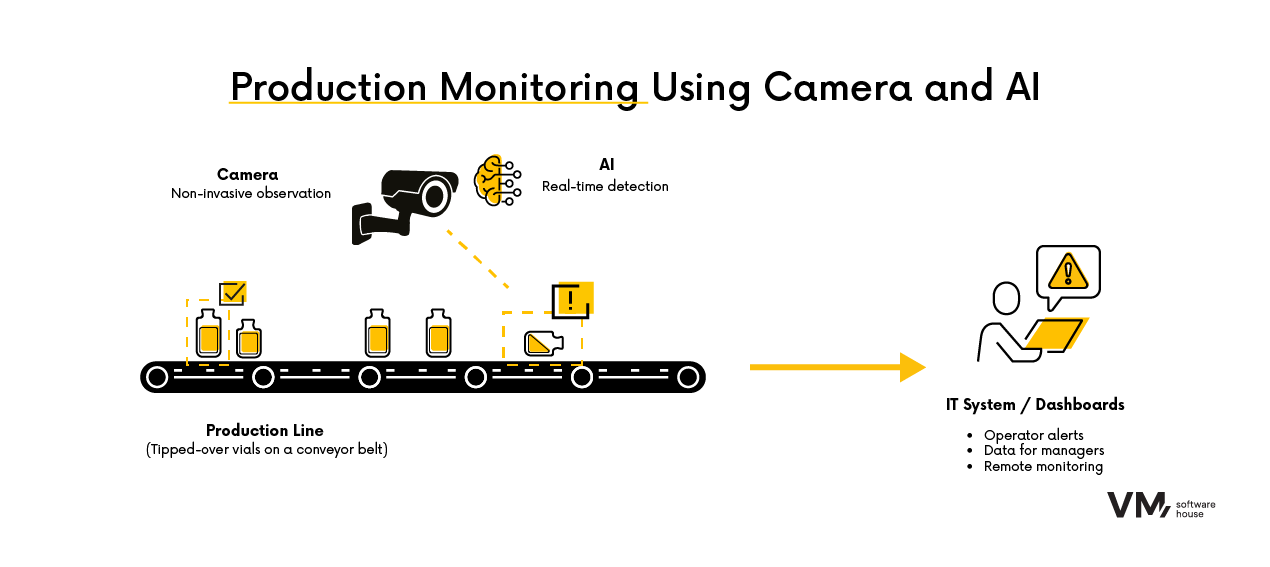

The team opted for a “camera-as-a-sensor” concept—non-invasive production monitoring using a single camera and advanced AI and machine learning software. The implementation process was carried out in several phases:

- Component selection – The right camera, lens, processing unit, signaling device, and housing were selected, taking into account the environmental conditions on the line.

- Hardware installation – The camera was installed without modifying the production line or its control systems.

- Training data collection – Over a defined period, the system captured visual data from the production process to build a dataset for training the AI model.

- Neural network training – The data was cleaned and prepared, then used to train a model capable of detecting fallen vials and counting correctly processed units.

- Testing and calibration – The system was validated on test datasets and during live production to ensure real-world performance.

- Edge case handling – The solution was enhanced with additional algorithms to handle challenging conditions (e.g., light reflections, irregular vial positions).

- Production deployment – The system was fully deployed, with remote monitoring and update capabilities.

All data was streamed to dedicated dashboards, giving managers real-time visibility into performance and enabling fast responses to any anomalies.

Results

- Reduced downtime – Operators receive instant alerts when a problem is detected

- Fast implementation – Full deployment from installation to go-live completed in just 3 months

- 99.89% detection accuracy for fallen vials

- No revalidation required – Fully non-invasive solution compliant with industry regulations

- Scalability – Can be deployed across other lines and products without hardware changes

- Low maintenance costs – No need for calibration, resistant to changing conditions

- Remote updates and monitoring – Continuous system improvement without disrupting production

How a Single Augmented Reality Deployment Helped Avoid the Costs of an International Engineering Team

Design, Development, DevOps or Cloud – which team do you need to speed up work on your projects?

Chat with your consultation partners to see if we are a good match.