Real-time data insights, faster time-to-market, and continuous monitoring—the benefits of using digital twins for simulation are numerous, provided the right conditions are in place. But which technology is better suited for your project: simulations or digital twins?

Though the idea of simulators and digital twins may seem cutting-edge, the concept has been around for some time. For instance, during the Apollo 13 mission in the 1960s, ground engineers were able to safely bring the astronauts back to Earth after an oxygen tank explosion. They did this by simulating a carbon dioxide filter replacement, which the astronauts then recreated on board.

As technology advances, businesses now leverage simulations and digital twins to optimize processes, test new ideas, and predict future outcomes. By developing digital twins, companies can improve product development, streamline operations, and enhance customer engagement through enriched experiences and interactions.

In fact, in 2019, digital twins were identified as one of the top ten strategic technologies that significantly improved decision-making processes for businesses. A McKinsey study reported that 70% of technology executives at large companies are investing more than $48 billion in digital twin technologies, with an anticipated compound annual growth rate of 58% by 2026.

This article delves into the core differences between simulations and digital twins to help you decide which solution is best for managing your projects.

Table of Contents

What is a Simulation?

A simulation is a virtual model of a process, system, or environment that allows you to test various scenarios without the risks and costs of using actual machinery. Simulations are primarily used for “what-if” analysis, creating a controlled environment where variables can be manipulated to observe outcomes.

Key characteristics of simulations include:

- Operating based on fixed inputs and assumptions

- Limited duration

- Static results derived from predetermined conditions

For decades, simulations have been widely used across industries to analyze how different factors impact processes. Automotive engineers, for example, use crash simulations to understand how vehicles behave during collisions. Medical professionals utilize patient simulators for performing complex surgeries, and economists create financial simulations to forecast the economic effects of certain policy decisions.

What are Digital Twins?

A digital twin is more than just a model—it’s a dynamic, virtual representation of a physical object, system, or process that is continuously updated with real-world data. Digital twins enable companies to optimize performance, predict future issues, and make real-time adjustments to operations.

Digital twins are powered by advanced technologies such as Internet of Things (IoT) sensors, artificial intelligence (AI), machine learning (ML), cloud computing, and data analytics. They are constantly connected to real-time data sources, often through embedded sensors in their physical counterparts, which feed live data back to the model to ensure synchronization with reality.

Key features of digital twins include:

- Continuous data updates to reflect real-time conditions

- Ongoing monitoring to provide continuous insights

- The ability to evolve as the physical object or system changes

In the manufacturing industry, for instance, digital twins are used to monitor equipment and predict maintenance needs before a machine fails. Similarly, digital twins of human organs are being used in healthcare to simulate personalized treatments.

Application of Simulation in Project Management

Simulations are ideal when you need to test multiple hypothetical scenarios or conditions over time but don’t require real-time data. This is particularly useful for new product designs in a controlled virtual environment without building physical machines.

Simulations allow you to model various conditions, such as extreme heat or pressure, to evaluate product performance. They also enable you to test multiple scenarios to identify optimal solutions during product development.

When should simulations be used to test scenarios in complex systems?

- Early-stage design: When it’s too costly or impractical to work with actual data.

- Theoretical testing: For evaluating scenarios without the need for physical resources.

- High-risk scenarios: When conducting actual experiments would be too dangerous or expensive.

Case Study: Manufacturing Environment Simulator in the Industrial Sector

For a client specializing in machinery manufacturing, we developed a project to simulate the production environment, aiming to reduce costs associated with implementing a new product for the end customer. This technological process allows us to detect errors early and better understand the impact of changes on the production process.

The creation of a basic simulation module involved five steps:

- Understanding network architecture: We gathered essential information about devices such as sensors and monitors, which helped us determine the necessary data for the simulator.

- Creating generic simulator components: We built common components to support sensors from different manufacturers, ensuring reusability and independence from the environment.

- Installing simulators in a Docker environment.

- Developing a user-friendly UI: This interface simplified the management of input data and simulations, making it easier for non-technical staff to use.

- Further development: This includes adding new sensors and generating alerts within the simulation to enhance functionality.

Benefits of Digital Twins Over Traditional Simulations

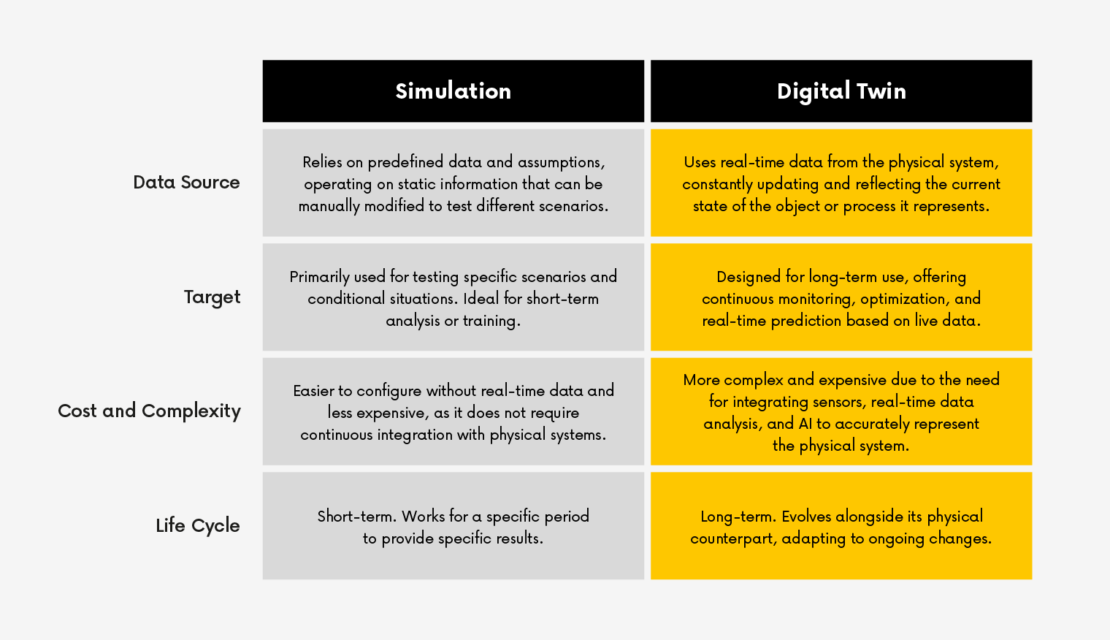

Simulations typically rely on static data sets or predefined inputs, meaning they lack live updates. However, a digital twin is the better solution if your project requires continuous feedback from the physical system—such as in manufacturing or smart cities where real-time monitoring is crucial.

A true digital twin works throughout the product life cycle (SDLC), from design to service, offering a more integrated solution across the entire process chain. The key benefits of implementing digital twins include:

- Improved product quality: The digital twin collects real-time data (e.g., from the manufacturing process), allowing you to see how the design may be flawed and enabling real-time adjustments.

- Optimization and automation: You can dynamically adjust operations, test scenarios, and optimize real-time performance with a digital twin.

- Continuous monitoring: Unlike simulations, which are typically event-based, digital twins provide constant surveillance.

- Faster development time: Digital twins allow for rapid iterations and optimizations of product designs, much faster than physical testing, as development teams don’t need to restructure raw data for each application.

A 2022 study found that digital twins can reduce the time required to deploy new AI-based capabilities by up to 60% and capital and operating expenditures by up to 15%.

However, implementing digital twins requires digital maturity within the organization. This includes a robust data infrastructure, such as PLMs (Product Lifecycle Management), PDMs (Product Data Management), and access to high-quality data from testing and real-world production environments.

Challenges of Implementing Digital Twins Compared to Simulations

When speaking with managers from various companies, three key challenges often emerge when implementing a digital twin:

1. Cost

Significant resource investment is required from the outset to achieve value. Building a digital twin demands larger investments, including IoT devices, cloud infrastructure, and data management tools.

2. Skills:

Implementing a digital twin requires:

- Data engineering expertise to support the data infrastructure

- The ability to model the product or object being twinned

- Advanced simulation and analytical skills to boost computational power

3. Data Quality: Digital twins depend on vast amounts of real-time data from sensors, which takes time to gather and requires highly skilled resources to manage and integrate.

How to Get Started with Digital Twins?

Given these challenges, companies need to determine the most appropriate use case for starting digital twin development. The following steps can help ensure a successful project:

- Digital Maturity Analysis: This step is crucial for assessing your organization’s digital maturity to identify current strengths and weaknesses and determine the infrastructure needed for development.

- Defining the Business Plan: It’s important to align the digital twin with a broader digital strategy, ensuring it fits into your company’s goals and can be leveraged for a competitive advantage.

- Start with an MVP: Begin by building a minimally viable product (MVP) that isn’t overly complex. Learn from this initial model and expand the digital twin framework based on those insights.

Which Solution is Right for Your Project?

Choosing between a simulation and a digital twin depends largely on your project’s specific goals and needs. If you require one-time analysis, scenario testing, or training, a simulation is likely the best option. However, a digital twin would be a more effective solution if your project demands real-time monitoring, continuous optimization, and data-driven decision-making.

Understanding these key differences will help you select the right tool, maximizing the technology’s impact on your project’s success. If you’d like to discuss your project needs, our experienced specialists can answer your questions and provide guidance on the best solutions.