Industrial manufacturing is becoming increasingly complex. Companies are under pressure not only to reduce costs and increase efficiency, but also to meet growing demands for safety, quality, and regulatory compliance. In this context, monitoring plays a critical role—it enables businesses to respond quickly to breakdowns, analyze the root causes of downtime, and optimize processes.

The problem? Traditional data collection methods are no longer keeping pace with today’s demands. Operator logs are often error-prone, physical sensors require expensive reconfiguration, and fragmented tracking systems are difficult to integrate. Enter the Camera-as-a-Sensor concept: a universal sensor powered by artificial intelligence and machine learning. This approach makes it possible to monitor production lines, machinery, and human operators in a flexible, non-invasive, and scalable way.

Table of Contents

Why Traditional Production and Machine Monitoring Is No Longer Enough

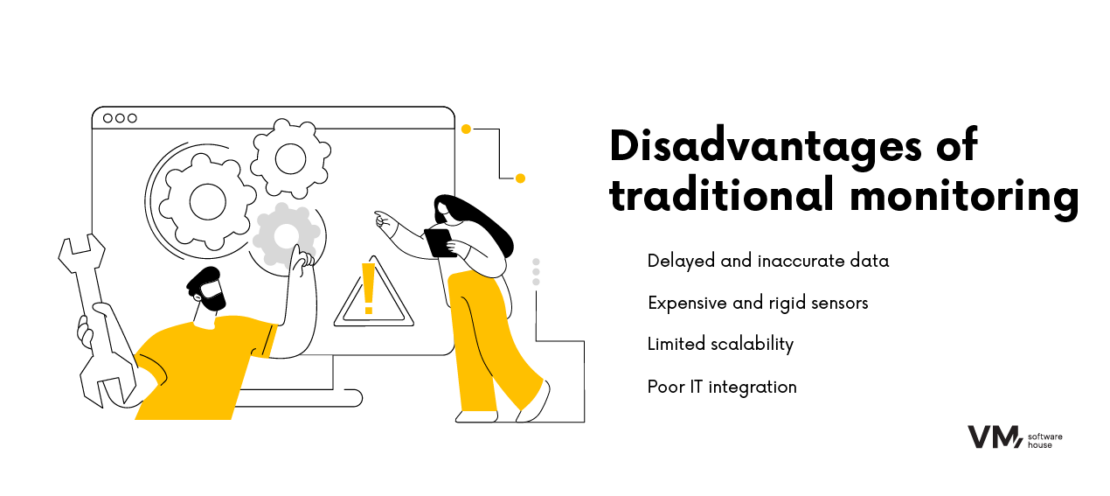

Before embracing a new approach, it’s essential to understand why existing methods are falling short. The biggest challenge in production monitoring lies in the lack of reliable data. Many factories still rely on manual operator reports entered via work cards. This reporting method is error-prone and doesn’t allow for real-time performance tracking. On the other hand, using physical sensors requires frequent reconfiguration whenever the product assortment changes—an issue especially burdensome in high-mix manufacturing environments.

Machine monitoring also presents multiple challenges. Downtime caused by breakdowns is extremely costly, yet integrating with PLC controller software is often off-limits due to regulatory and validation constraints. Traditional sensors require periodic calibration, leading to additional line stoppages and higher maintenance costs.

Operator monitoring is just as critical. As the focus on ergonomics and workplace safety intensifies, traditional systems—such as RFID, RTLS, or motion tracking—are proving inadequate. These technologies are expensive to deploy, time-consuming to implement, and hard to scale. What’s more, the data they generate is often fragmented, making it difficult to leverage consistently.

Camera as a Sensor – How AI and Computer Vision Enable Smart Monitoring

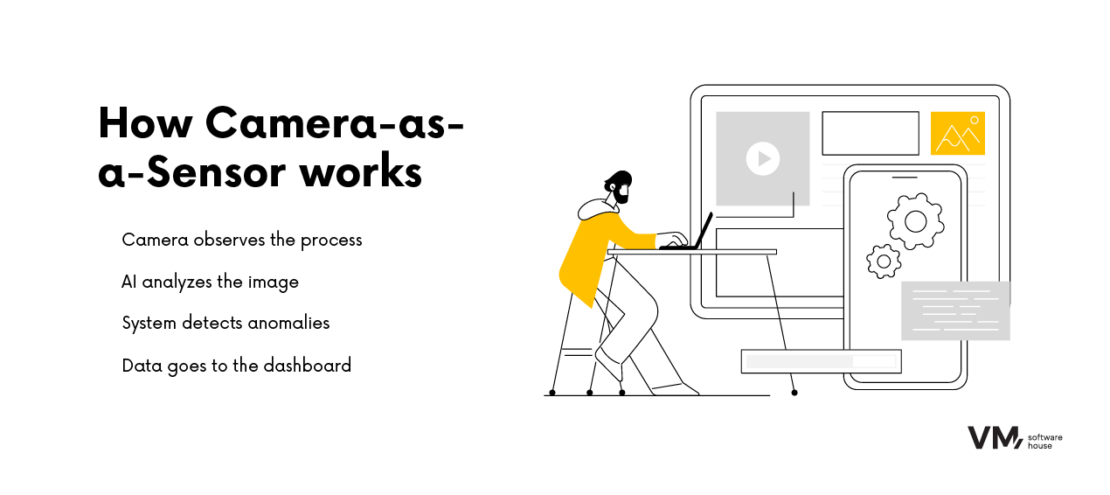

The Camera-as-a-Sensor concept uses cameras as universal sensors to monitor processes, machines, and human operators. Unlike traditional sensors, cameras do not interfere with the machinery’s structure or software—they passively observe operations from the outside.

The video feed is analyzed using advanced Computer Vision algorithms, combined with AI and machine learning models. As a result, the system can:

- detect anomalies,

- count products,

- track line performance,

- and assess operator behavior in terms of ergonomics and safety.

Importantly, the system evolves over time—models continuously learn from new data, and new capabilities can be deployed remotely without halting production.

Integrating Camera-as-a-Sensor with Existing Infrastructure

One of the greatest advantages of this approach is its ease of integration. All it takes to deploy the system is a camera, a computing unit, analytics software, and a data visualization dashboard. There’s no need to interfere with the machines or their controllers, eliminating risks related to revalidation or voiding manufacturer warranties.

Additionally, the system can be seamlessly integrated with existing IT solutions—such as MES, ERP, or SCADA systems—so that camera data becomes part of a broader production management ecosystem. Thanks to its modular architecture, Camera-as-a-Sensor can be easily scaled or transferred across production lines or even entire facilities.

Business and Technical Benefits of Implementing Cameras as Sensors in Manufacturing

Camera-as-a-Sensor delivers value across technical, business, and strategic levels.

- From a technical perspective, the system is easy and cost-effective to configure, with low maintenance requirements. It doesn’t require any modifications to the machines, and its flexible software can easily adapt to changing production environments.

- On the business side, the key advantages are reduced downtime and increased line efficiency. The system provides detailed process data that helps identify inefficiencies and optimization opportunities. An added benefit is improved operator safety and workplace ergonomics.

- The most important gains, however, are strategic. Camera-as-a-Sensor gives manufacturers independence from machine vendors and enables full system development at the software level—without the need for costly hardware upgrades. It naturally aligns with Smart Factory and Industry 4.0 frameworks, paving the way for long-term competitive advantage.

Implementing the Camera-as-a-Sensor System

The implementation process is best understood through our 4D Methodology, which includes four key phases: Discovery, Definition, Delivery, and Direction.

- Discovery: This phase involves a production process audit and identification of critical monitoring points. Regulatory and technical constraints are also assessed, and business objectives are defined—such as reducing downtime or improving the OEE (Overall Equipment Effectiveness) score.

- Definition: At this stage, the system architecture is designed. Cameras, computing units, and integration methods with existing IT infrastructure are selected. A risk assessment is conducted, and cost estimates along with the implementation timeline are developed.

- Delivery: the system is physically installed, followed by validation testing. Special attention is given to handling edge cases that may occur in a real production environment.

- Direction: The most critical phase. Here, the system enters a continuous improvement loop—remote updates, new functionalities, and strategic client support are introduced. This ensures that the solution evolves alongside the factory, becoming a core enabler of long-term digital transformation.

Case Study: AI-Powered Production Monitoring in the Pharmaceutical Industry

A compelling example of the effectiveness of the Camera-as-a-Sensor concept comes from a global pharmaceutical company. The firm faced frequent production line stoppages caused by vials tipping over during packaging. The issue was significant, as the line handled seven product variants—ranging from small glass vials to larger plastic containers (7 to 100 ml). Regulatory constraints added complexity: any modification to the machine’s PLC or mechanical structure would have triggered a costly and time-consuming revalidation process.

The solution involved installing a single camera, with footage analyzed by AI and machine learning algorithms. The system was able to:

- detect fallen vials in real time,

- alert operators immediately,

- count products, and

- monitor line efficiency.

Data was streamed to dedicated dashboards, giving managers real-time visibility into performance metrics.

The entire deployment took just three months. No revalidation was required, detection and counting accuracy was high, and the system allowed for remote updates and easy scaling to other production lines.

The Future of Cameras as Sensors

The Camera-as-a-Sensor concept aligns with the key megatrends of Industry 4.0. In the coming years, we can expect a continued shift away from traditional physical sensors toward flexible, AI-powered digital solutions. Cameras will become a core component of predictive maintenance systems, enable the development of Digital Twins, and support comprehensive analysis of ergonomics and workplace safety.

In the long term, the vision is clear: a factory monitored through the eyes of artificial intelligence, where visual data becomes the foundation for real-time decision-making. This is the kind of technology that will power the factories of the future—agile, efficient, and resilient in the face of unforeseen disruptions.