Table of Contents

Challenges in Maintenance – Why Traditional Approaches Fall Short

In manufacturing plants, every machine downtime translates into real costs – delivery delays, lost productivity, and often quality issues. Even with preventive maintenance, unexpected breakdowns still occur and require fast intervention.

Traditional diagnostics often rely on the experience of engineers or verbally shared knowledge within the team. Vendor documentation and past incident reports tend to be scattered, and finding them in a crisis consumes time—something that’s always in short supply during a breakdown.

Shift work further complicates things, as knowledge doesn’t always transfer seamlessly between operators and maintenance staff.

The result? Longer repair times (MTTR), lower machine availability, and rising costs for the company.

How Does Herodotus Work?

Herodotus is an intelligent assistant powered by artificial intelligence and Retrieval-Augmented Generation (RAG). It supports engineers and operators in resolving technical issues faster.

Access to Knowledge in Seconds

The system analyzes manufacturer documentation, failure history, technician notes, and internal safety procedures. This allows engineers to ask questions in natural language and receive precise answers based only on verified sources—minimizing the risk of AI “hallucination.”

Reducing MTTR and Increasing MTBF with AI

Herodotus shortens diagnosis and repair times (MTTR – Mean Time to Repair) while extending the mean time between failures (MTBF). The result: greater equipment availability, fewer downtimes, and real savings in maintenance operations.

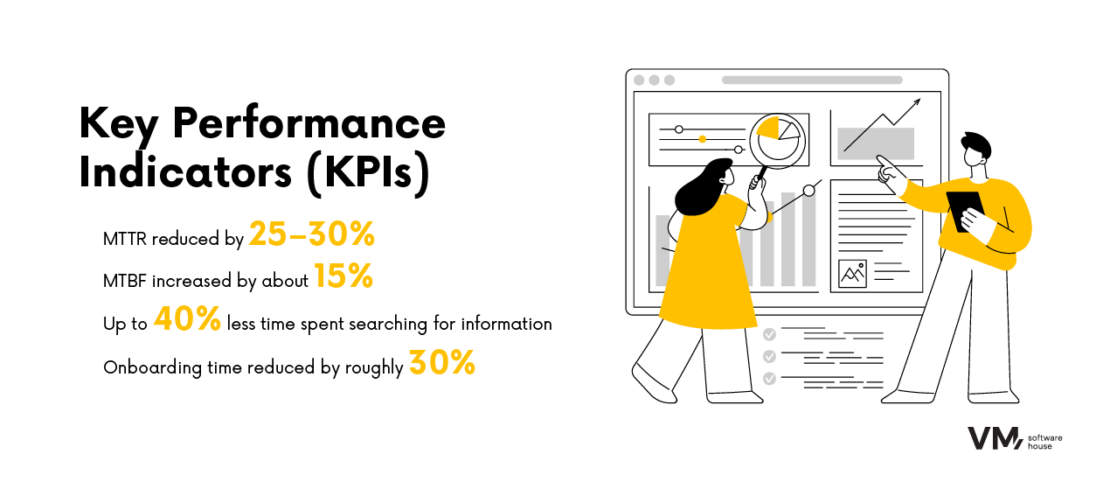

Key Performance Indicators (KPIs)

During the system pilot, the following results were achieved:

- MTTR – Repair time reduced by an average of 25–30%

- MTBF – Time between failures extended by 15%

- Technician time savings – Up to 40% less time spent searching for information

- Faster onboarding – 30% reduction in training time for new employees

These numbers show that Herodotus isn’t just another theoretical tool—it’s a real, practical support system for maintenance teams.

Pilot Results – Benefits for Technicians and Operators

Technicians appreciated the ability to instantly refer to past cases and proven solutions. Operators—especially those on night shifts—gained 24/7 access to expert knowledge, even when specialists weren’t on-site.

In some cases, repair times were reduced from around an hour to just a few minutes. When the system didn’t have a ready answer, it clearly stated “I don’t know,” allowing teams to consult manuals or contact OEM support promptly. This transparency made the entire incident response process faster and more efficient.

As a result, not only did the speed of troubleshooting improve, but also the sense of autonomy and confidence among production line staff.

The system is now being deployed at a larger scale across more departments, progressively expanding benefits and boosting operational efficiency.

Business Benefits for Managers

For production and maintenance managers, Herodotus delivers:

- Reduced downtime costs through faster repairs

- Better machine utilization

- More efficient planning of service resources

- Shorter onboarding time for new operators

- Unified knowledge across teams—regardless of shifts or staff turnover

Additionally, the system is highly flexible—it can be deployed on-premise or in the cloud (Azure, AWS, GCP), and integrated with MS Teams or other communication platforms.

Herodotus in Practice – More Than Just Maintenance

Although initial implementations focused on supporting maintenance departments, Herodotus also proves valuable across other business areas:

- Training – automatic generation of tests and educational materials

- IT project management – instant access to documentation and tickets

- Construction – verification of contracts and handover protocols

- Finance & Controlling – fast search across reports and case studies

Herodotus Security – Full Control Over Your Data

Implementing AI solutions in manufacturing and maintenance environments requires the highest standards of data security. Herodotus is designed to ensure maximum information protection and eliminate risks associated with AI use in industrial settings.

Security

- The system operates exclusively on pre-approved data sources (manufacturer documentation, internal procedures, failure logs). This eliminates the risk of random AI “hallucinations” and guarantees full control over outputs.

- In on-premise mode, all data remains entirely within the client’s infrastructure—no risk of external leakage.

- In the cloud version (Azure, AWS, GCP), Herodotus offers enterprise-grade security, high availability, and native integration with communication tools such as MS Teams.

- The knowledge base updates automatically—the system detects new or modified files and makes them instantly searchable.

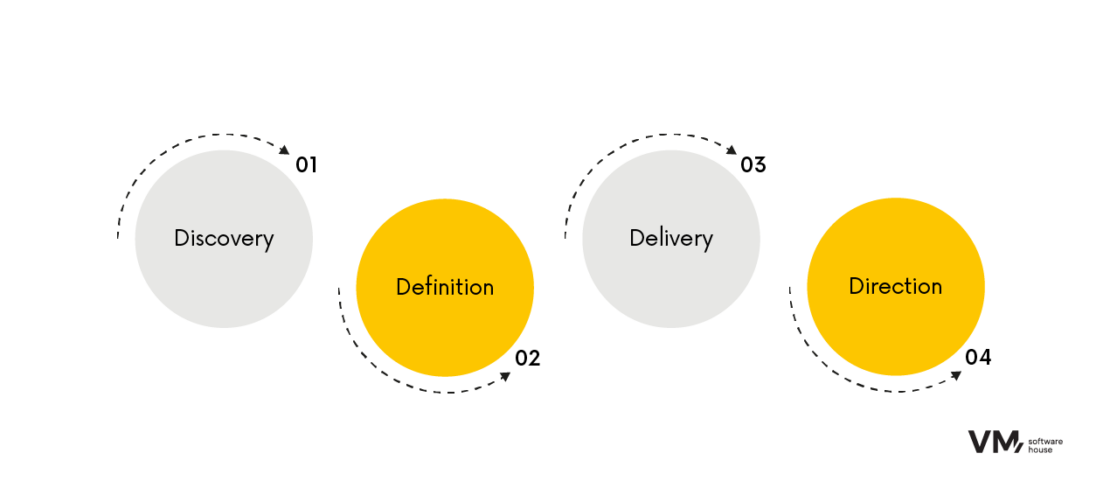

Our 4D Methodology – The Foundation of Successful Deployments

Herodotus is developed and scaled using our proven 4D implementation framework:

- Discovery

Identify challenges, analyze needs, and define business goals. - Definition

Design the solution architecture, define risks, and estimate costs. - Delivery

Deploy, test, and launch the system smoothly. - Direction

Strategically support the client long-term: evolve the product, drive innovation, and scale operations.

This approach makes Herodotus more than a tool—it becomes a long-term partner in boosting operational efficiency.

Long-Term Support and Growth Strategy

The greatest value of Herodotus lies not only in providing rapid support during breakdowns, but also in its strategic contribution to production development. The system continuously learns from new cases and automatically updates its knowledge base. With each passing month, it becomes more effective and valuable.

Herodotus is not a one-time implementation—it grows alongside your organization. As your company evolves, you can:

- Scale the system to new production lines, departments, or entire plants

- Integrate it with other systems (ERP, CMMS, MES, quality systems) for a complete production data ecosystem

- Expand its applications – from maintenance to quality control, reporting, and financial analytics

- Introduce AI-powered innovations supporting predictive maintenance and automated resource planning

If you want to see how Herodotus can improve machine reliability and reduce downtime costs in your plant, get in touch with us – we’ll show you how it works in practice.